Did you know that to shut down a production line could cost $5,000 per minute?

Hence the necessity of high-precision machinery tooling in order to make deliveries on time across your line of products. This is key to avoid high costs and other expenses related to precision tooling.

Learn more about these losses and how Meins Industries can be there for you and your business.

Costs Within the Manufacturing Industry

Precision tools can be the best ally or the sworn enemy at any factory. It can help businesses achieve a steady production. Nevertheless, it can also become the financial leak your business can’t take for long.

What’s the case within your business?

Bad quality costs. Setbacks like rejected merchandise due to bad quality are added to these costs, they can be avoided with the right services.

Machinery costs. The same way, the failure of these precision tools or the need to replace them is a cost due to the time involved. This also reflects in a product shortage that results in delivery delays.

The companies within the manufacturing industry are aware of how much bad quality, delays in deliveries and set backs cost. It is very important to foster the creation and upkeep of enterprises devoted to the creation and procurement of precision tools designed for the industry sector, such is the case of Meins Industries.

Precision Machinery Solutions

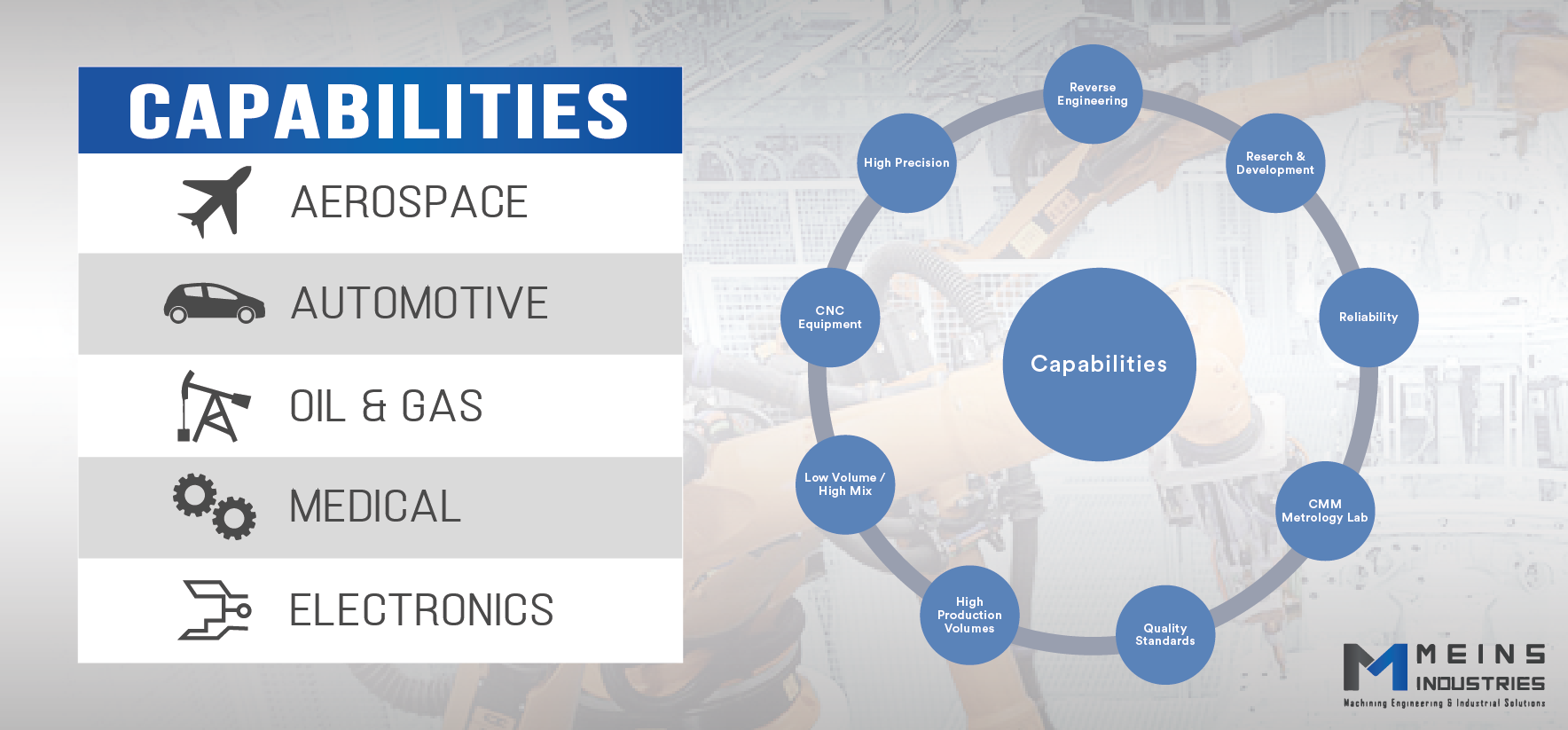

Meins Industries designs and manufactures several part numbers and complex and precision tools for the automotive, aerospace, medical, construction, oil and gas industries.

Meins Industries promise to its clients is: “Your production time and delivery will never be affected because of bad servicing or a delay on our side”. Some of the manufacturers that rely on Meins Industries products are: Mazda, Audi, Ford, BMW, Nissan, Toyota and Mercedes-Benz.

Meins Industries was part of The Bridge Accelerator, a binational program that fosters the participation of local companies in the chain of supply of large scale manufacturing enterprises.

Your business could also be part of this program, register here and accelerate your business.

Meins Industries relies on the machinery and very specialized equipment with the latest capabilities to achieve your company’s expectations in a time, with the formality an quality needed. They also have a CMM lab that can certify every piece of equipment manufactured through an inspection report.

You know you can count on a company that uses coordinates measuring, probe arms and scanners, 3D modeling and even reverse engineering. A business with such dedication to its duty can solve any problem with pleasure and in an innovative fashion.

Meins Industries offers this wide range of services in order to ensure better quality and timely delivery of your products.

Schedule a meeting with a Meins Industries executive, today!